Products

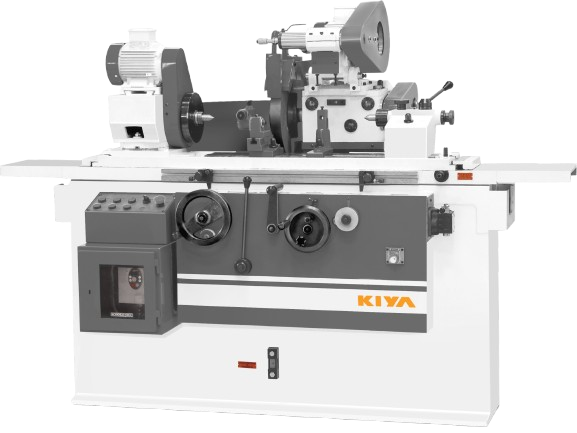

Overview

EG series CNC External Cylindrical & Track grinding machines are the perfect solution for all grinding companies seeking the greatest flexibility. The Machine bed is made of one piece close special graded grain cast iron box structure design with optimum ribbing provides high static and vibration free dynamic rigidity to the machine. Artificial Stress reliving process carried for more dimensional stability.

Features

Precision hand scraped V-Flat table guide ways for Z-axis and Cross Roller slide for X-axis with centralised lubrication.

Laser calibrated axis for high precise positioning Accuracy and Repeatability.

Machine is provided with Cartridge type Wheel spindle with two match pair sets of Angular Bearing for smooth performance while material cutting. Spindle is driven by induction motor and transmitted by Poly V belt.

Specification

| Model | ||||||

|---|---|---|---|---|---|---|

| Description | Unit | EG 450 | EG 600 | EG 800 | EG 1000 | EG 1200 |

| Swing over table | mm | 300 | 300 | 300 | 300 | 300 |

| Admit between centres | mm | 450 | 600 | 800 | 1000 | 1200 |

| Work head Center Height | mm | 150/200 | 150/200 | 150/200 | 150/200 | 150/200 |

| Grinding Diameter Max (O.D.) | mm | 275 | 275 | 275 | 275 | 275 |

| Grinding Diameter Min (O.D.) | mm | 5 | 5 | 15 | 15 | 15 |

| Max. Weight of Job Between Center | Kg | 120 | 120 | 120 | 120 | 120 |

Overview

IG series internal cylindrical grinding machines are the perfect solution for all grinding companies seeking the greatest flexibility. The Machine bed is made of one piece close special graded grain cast iron box structure design with optimum ribbing provides high static and vibration free dynamic rigidity to the machine. Artificial Stress reliving process carried for more dimensional stability.

Features

The Precision hand scraped V-Flat table guide ways for X & Z-axis with centralised lubrication.

Laser calibrated axis for high precise positioning Accuracy and Repeatability.

Specification

| Model | ||||||

|---|---|---|---|---|---|---|

| Description | Unit | IG-30 | ||||

| Max. Rotating Diameter | mm | 300 | ||||

| Min. Grinding Diameter | mm | 16 | ||||

| Max. Grinding Diameter | mm | 280 | ||||

| Grinding depth max. | mm | 80 | ||||

| Maximum job weight | kg | 50 | ||||

| Work Center Height from Floor | mm | 1100 | ||||

| Maximum Chucking Dia. | mm | 300 | ||||

| Centre height from Slide | mm | 212 | ||||

Overview

HCG series hydraulic cylindrical grinding machine are the perfect solution for all grinding companies seeking the greatest flexibility. The Machine bed is made of one piece close special graded grain cast iron box structure design with optimum ribbing provides high static and vibration free dynamic rigidity to the machine. Artificial Stress reliving process carried for more dimensional stability.

Features

The Precision hand scraped V-belt table guide ways with continuous lubrication. Longitudinal hand travel of the table is by rack and pinion arrangement and auto- matic travel by hydraulic mechanism.

The Hydro Dynamic wheel head spindie is made of case hardened Nickel Chrome alloy steel ground and micro finished & runs in adjustable White metal bush bear- ing to achieve vibration free rotation with high accuracy and long life. Drive to the wheel head is transmitted by poly V-belts.

Specification

| Model | ||||||

|---|---|---|---|---|---|---|

| Description | Unit | HCG-E 450 | HCG-E 600 | HCG-E 800 | HCG-E 1000 | HCG-E 1200 |

| Swing over table | mm | 300 | 300 | 300 | 300 | 300 |

| Admit between centres | mm | 450 | 600 | 800 | 1000 | 1200 |

| Work head Center Height | mm | 150/200 | 150/200 | 150/200 | 150/200 | 150/200 |

| Grinding Diameter Max (O.D.) | mm | 275 | 275 | 275 | 275 | 275 |

| Grinding Diameter Min (O.D.) | mm | 5 | 5 | 15 | 15 | 15 |

| Max. Weight of Job Between Center | Kg | 70 | 70 | 120 | 120 | 120 |

HCG INTERNAL

CNC Internal Cylindrical Grinder

| Model | ||||||

|---|---|---|---|---|---|---|

| Description | Unit | HCG-I 450 | HCG-I 600 | |||

| Capacity | ||||||

| Swing Over Table | mm | 350 | 350 | |||

| Work Head Center Height | mm | 175 | 175 | |||

| Grinding Diameter Max I.D. / Depth | mm | 100 / 80 | 100 / 80 | |||

| Grinding Diameter Range I.D. / Depth | mm | 12 / 20 | 12 / 20 | |||

| Max. Weight of Job with Chuck | mm | 50 | 50 | |||

*Machine also available with single axis CNC

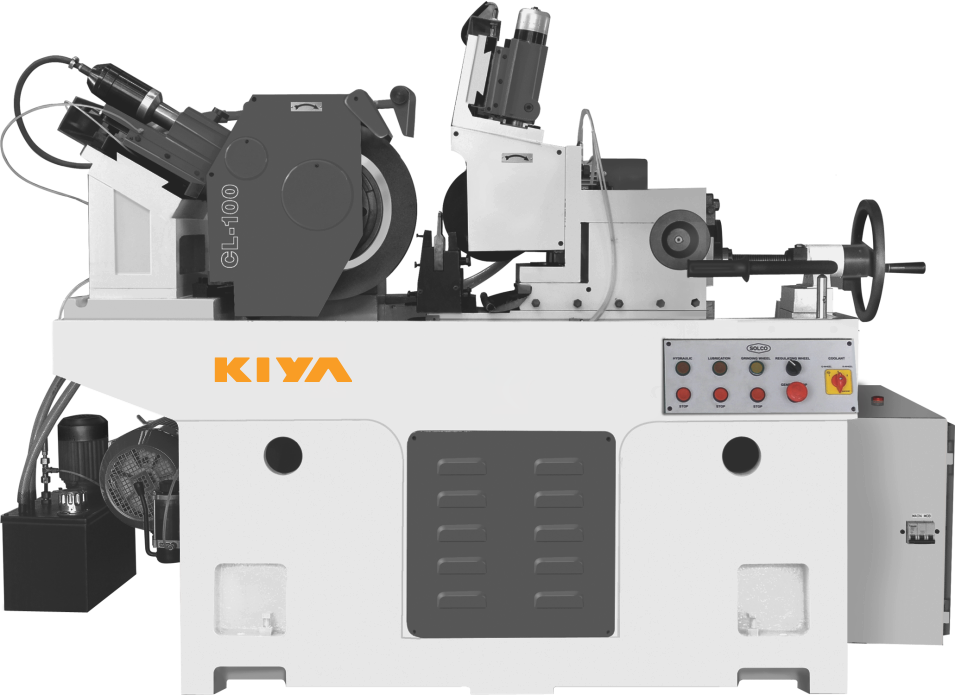

Overview

CL series Hydraulic Centerless grinding machines are the perfect solution for all grinding companies seeking the greatest flexibility. The Machine bed is made of one piece close grained cast iron box structure design with optimum ribbing provides high static and vibration free dynamic rigidity to the machine. Artificial Stress reliving process carried for more dimensional stability.

Features

The cantilever Grinding wheel spindle Head is fixed to the bed and is of sturdy design to ensure maximum Rigidity and smooth operation.

Grinding wheel spindle is made of special alloy steel especially heat treated ground and lapped to achieve very high dimensional stability, accuracy and long life.

Hydro Dynamic Grinding wheel spindle runs in phosphorus bronze bush bearings with oil lubrication system. Drive from main motor to spindle is through V-belts and V-grooved pulleys.

Specification

| Model | ||||||

|---|---|---|---|---|---|---|

| Description | Unit | CL-100 | ||||

| Capacity | ||||||

| Min. Grinding Diameter | mm | Ø 3 | ||||

| Max. Grinding Diameter | mm | Ø 100 | ||||

| Wheel Head | ||||||

| Grinding Wheel Size (OD x ID x Width) | mm | Ø 400 x Ø 228.5 x 150 | ||||

| Discard Wheel Diameter | mm | Ø 280 | ||||

| Grinding Wheel Spindle Size | mm | Ø 65 | ||||

| Grinding Wheel Motor Power | Kw/hp | 5 / 7.5 | ||||

*Machine also available with single axis CNC and Hydruolic Plunge Mechanism.